Precision, hand delivered

On-brand, in-hand, and ahead of the curve

This soldering iron slots straight into iFixit’s ecosystem – but it doesn’t just blend in, it levels up. We dialled in a design language that speaks fluent iFixit: clean, honest, and purpose-built. But then we sharpened the edges, refining every curve and contour to create a tool that feels as good as it looks.

It’s sleek without being flashy, smart without being complicated, and comfortable enough to disappear in your hand when you’re in the zone. A quiet achiever, by design.

Fix, don’t flick

This tool isn’t just for soldering – it’s for starting a movement. We designed it to champion repair over replacement, to make fixing feel less like a chore and more like a flex.

From tight component work to quick fixes, it empowers users to extend the life of their gear and stick it to planned obsolescence while they’re at it.

Sharp where it counts

This isn’t some watered-down consumer gadget pretending to be pro. It’s built from the inside out for speed, accuracy, and finesse. Instant heat-up, surgical control, and a tip that means business—it’s the kind of tool that turns first-timers into lifelong fixers. It’s precision with punch.

The repairable repair tool

Here’s a wild idea: what if the tool you use to fix stuff was also… fixable? Radical, we know. This soldering iron was built with disassembly in mind. Modular components, no proprietary traps, and screws where screws should be.

Because repairability shouldn’t stop at the things you’re working on – it should include the tools you’re working with.

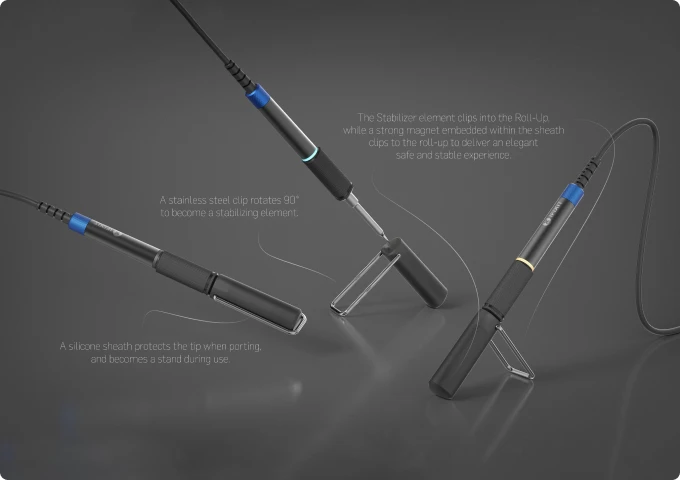

Beauty in the details, purpose in the form

This is what happens when nothing’s left to chance. From the anti-roll geometry to the grip-enhancing textures, every aspect of the soldering iron was obsessively refined—not just to look sharp, but to work smart.

The body shape fits naturally in the hand; the surface finishes feel precise, not precious. It’s design that disappears in use, but rewards a closer look. No fluff, no filler – just form that follows real function, beautifully.

“Like the soldering iron they helped design, the team was fast, responsive, and highly skilled. They quickly grasped our users' needs and delivered an intuitive, user-friendly design with impressive efficiency.”

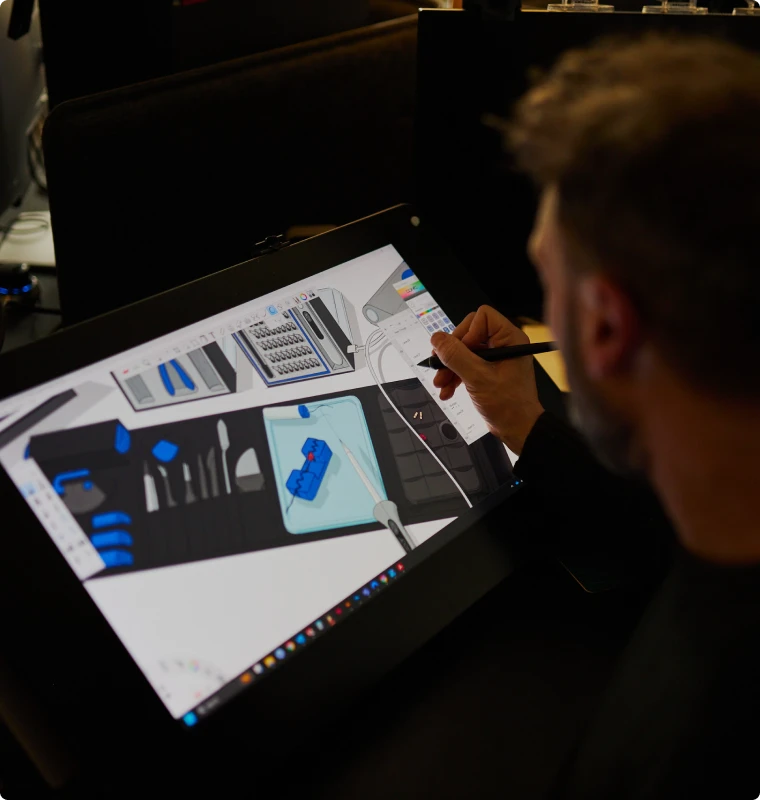

The process behind the precision

This was a hands-on, iterative process from day one. We 3D printed. We tested. We refined. Getting the in-hand feel just right meant building and evaluating physical prototypes, over and over, because designing for use means designing in context.

We also zoomed out to think system-wide: how this tool integrates into iFixit’s ecosystem, how it stores, travels, and complements the broader kit. It’s the kind of process that doesn’t always show up in the final form, but it’s there in every detail.

A collaboration that’s more than cosmetic

This project wasn’t about ticking boxes. It was about designing a tool that means something – to the user, to the planet, and to a repair-first culture.

Together with Spanner PD and iFixit, we turned an idea into a tool that does more than solder – it shifts mindsets. One fix at a time.